Industrial-grade tube plugs for every exchanger. Zero leaks. Ultimate safety.

Choose KRAIS HEP & FFP plugs – engineered for reliability and repeatable installation. Available in two versions: general use and fin-fan applications!

Why KRAIS T_APPL tube plugs? / Key Benefits

Torque-controlled mechanical seal – always repeatable, always reliable

Each plug uses a torque-controlled expansion system, ensuring a consistent mechanical seal every time. No guesswork—just reliable, leak-proof performance in every installation.

No hydraulic pumps or high-pressure tools needed

Installation requires only a standard manual torque wrench. There’s no need for hydraulic pumps, high-pressure tools, or complex equipment, making field operations faster and safer.

No tube deformation – even under severe thermal cycling or vibration

Plugs expand uniformly inside the tube, delivering a tight seal without distorting the tube wall—even under repeated temperature changes or intense mechanical vibration during service.

Simple removal with slide hammer for tube inspection or replacement

Every plug features a threaded extraction system, allowing quick, safe removal with a dedicated slide hammer—so tube inspection, cleaning, or replacement can be performed without difficulty.

Ready for toughest environments: power, petrochemical, chemical, marine

Designed for the world’s harshest industrial environments—KRAIS plugs deliver dependable sealing in power, petrochemical, chemical, and marine applications, where safety and uptime are critical.

Sizes and materials for every industry, including custom-engineered plugs

Available in a wide range of sizes and materials to suit any industry. Custom plugs are rapidly engineered and manufactured for non-standard tubes, special alloys, or demanding project requirements.

Certificates

and proven quality

Certified manufacturing (ISO 9001) – full material traceability

KRAIS operates an ISO 9001-certified manufacturing facility, guaranteeing rigorous quality control and complete material traceability for all plugs supplied to customers worldwide.

PED certification in progress

KRAIS is actively implementing PED (Pressure Equipment Directive) certification processes to meet European requirements, ensuring even higher standards of safety and compliance for our products.

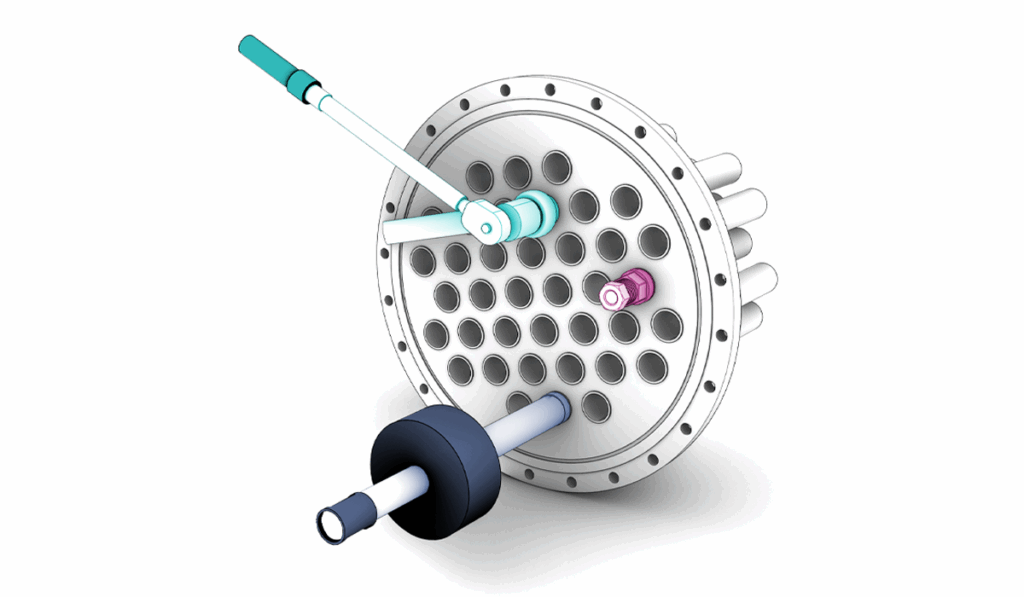

T_APPL HEP Series

Tube plugs for general use

The KRAIS T_APPL HEP series tube plugs is a specialized, mechanical plug engineered for use inwide range of heat exchangers. Designed for high-pressure environments, it offers secure sealing without damaging the tube wall, even under severe thermal stress or vibration.

-

High-pressure, mechanical plug for heat exchangers, boilers, condensers

-

Radial expansion delivers secure, leak-tight seal

-

Installation with a manual torque wrench only – no pumps, no surprises

-

For all standard tube diameters (see table)

-

No damage to tube wall – safe, reliable, repeatable

-

Easy removal: dedicated slide hammer for safe extraction

-

Material options: Carbon Steel (CS), Admiralty Brass (BR), Stainless Steel (SS), Cu-Ni (CN)

T_APPL FFP Series

Fin-fan applications

The KRAIS T_APPL HEP series tube plugs is a specialized, mechanical plug engineered for use inwide range of heat exchangers. Designed for high-pressure environments, it offers secure sealing without damaging the tube wall, even under severe thermal stress or vibration.

Specialized plug for air-cooled fin fan exchangers

Optimized for difficult/restricted access: long-reach push-in spanner for deep/narrow tubes

Same high-pressure mechanical sealing as HEP, with easier access

Designed for tubesheet locations with poor visibility or limited working space

All advantages of the HEP series (torque-controlled, removable, safe for tube)

Tools and accessories

General applications

A torque wrench should be used to ensure correct plug installation.

Slide hammer, connected to the threaded part of the plug, allows safe extraction of the plug for tube inspection or replacement

Fin-fan applications

A torque wrench should be used to ensure correct plug installation.

A set of tools: specially designed installation tool for Fin-Fan applications and dedicated slide hammer, connected to the threaded part of the plug.

Selection Guide & Technical Table

STEP 1

Accurately measure tube ID with precision tools (see our KRAIS Tube Hole Gauge)

STEP 2

Check the effective sealing region inside the tube

STEP 3

Cross-check size with the charts below

STEP 4

Select material: CS, BR, SS, CN

Order

Contact us for custom requirements or support

Plug Sizing & Custom Orders

If your application doesn’t match standard plug sizes (due to weld beads, unusual geometry, etc.), KRAIS provides custom-engineered plugs for any requirement – with rapid production and global delivery.

Installation & Removal – How it works

Tube plug installation

Prepare and clean tube (use MiniDrill-500 if needed for heavy deposits/rust)

Lubricate threads (copper-based for CS/Brass, nickel-based for SS/CuNi)

Insert plug, position correctly

Tighten to specified torque using calibrated manual torque wrench

For FFP series: use long-reach push-in spanner for hard-to-access tubes

Tube plug removal

Loosen plug nut gently

Use slide hammer connected to plug thread for safe extraction

No tube wall damage, easy for re-inspection or replacement