Tube expansion procedure and best rolling practices

Basic tube expansion procedure

The following suggestions are offered to aid in the setting up process for rolling tubes into a heat exchanger or boiler. A good start assures good end results:

- Pick 3 to 5 tubes in the unit to be rolled and complete the formula on the page A-1. It is important that the Measurements used in the set- up are actual, never use averaged dimensions.

- After the worksheet is finished, start setting up the torque control motor by test rolling the first of the 5 tubes. The first test roll must be done with the airetrol or electric rolling motor set for low torque to avoid over rolling.

- Measure the tube ID after rolling. If more expansion ls needed, increase the torque setting on the control and roll the second tube. Check the finished ID this step may have to be repeated on tube # 3. By this time, the torque setting should be correct.

- Roll tubes 4 and 5 to double check the set-up. These tubes should measure as calculated within the allowable tolerance:

- Condenser tubes 10-17 BWG +/- 0.001”

- Condenser tubes 18-24 BWG +/- 0.0005”

- Boiler tubes 4-10 BWG +/- 0.002”

- Boiler tubes 12-16 BWG +/- 0.001”

- The rolling control is now set and ready to roll the rest of: the tubes in the unit. The use of the torque control system will ensure the uniform tightness of all tubes.

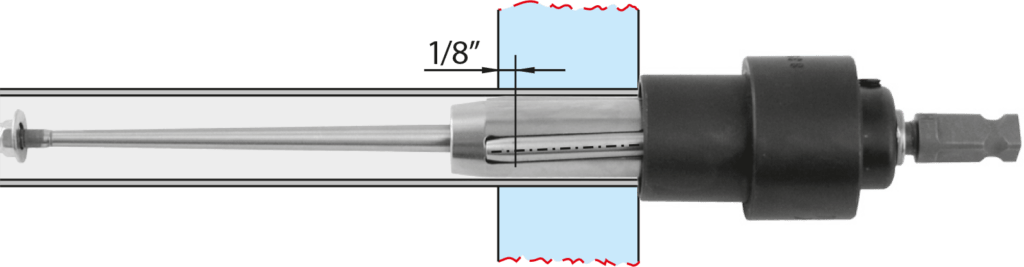

Setting Condenser Expander

Locate high point of roll approx 1/8” inside back of tube sheet and thrust collar must be touching tube sheet.

Note!

Re-roll all test tubes that were under size. To ensure the best tool life and the highest quality tube to tube sheet contact, periodic cleaning of the expander is necessary. Proper lubrication of the rolls, mandrel and thrust bearing is a must!

Boiler setup guide

The ends of all tubes, suspension tubes, and nipples of water tube boilers and superheaters shall project through the tube sheets or headers not less than 1/4” nor more than 3/4” before flaring. Where tubes enter at an angle, the maximum limit of 3/4” shall apply only at point of least projection. The tubes shall be expanded and flared to an outside diameter of at least 1/8” greater than the diameter of the tube hole or they may be flared, rolled and welded except as provided in pwt 11.2; or rolled and seal welded without flaring provided the throat of the seal weld is not more than 3/8” and tubes are re-expanded after welding.

- Tubes to protrude inside drum 1/4” minimum to 3/4” maximum.

- Outside diameter of flare to be 1/8” larger than tube sheet hole.

- Tube to be rolled past back of tube sheet 1/4” to 3/8”.

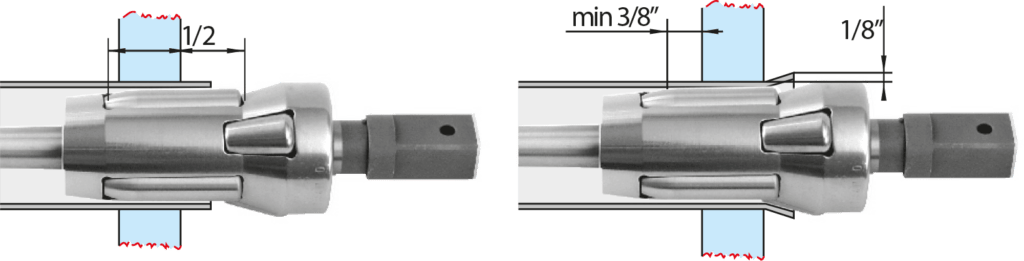

Setting Boiler Expander

Short straight roll set approx half way into tube sheet. Tube rolled 3/8” back of tube sheet. Flared tube diameter 1/8” larger than tube sheet hole.

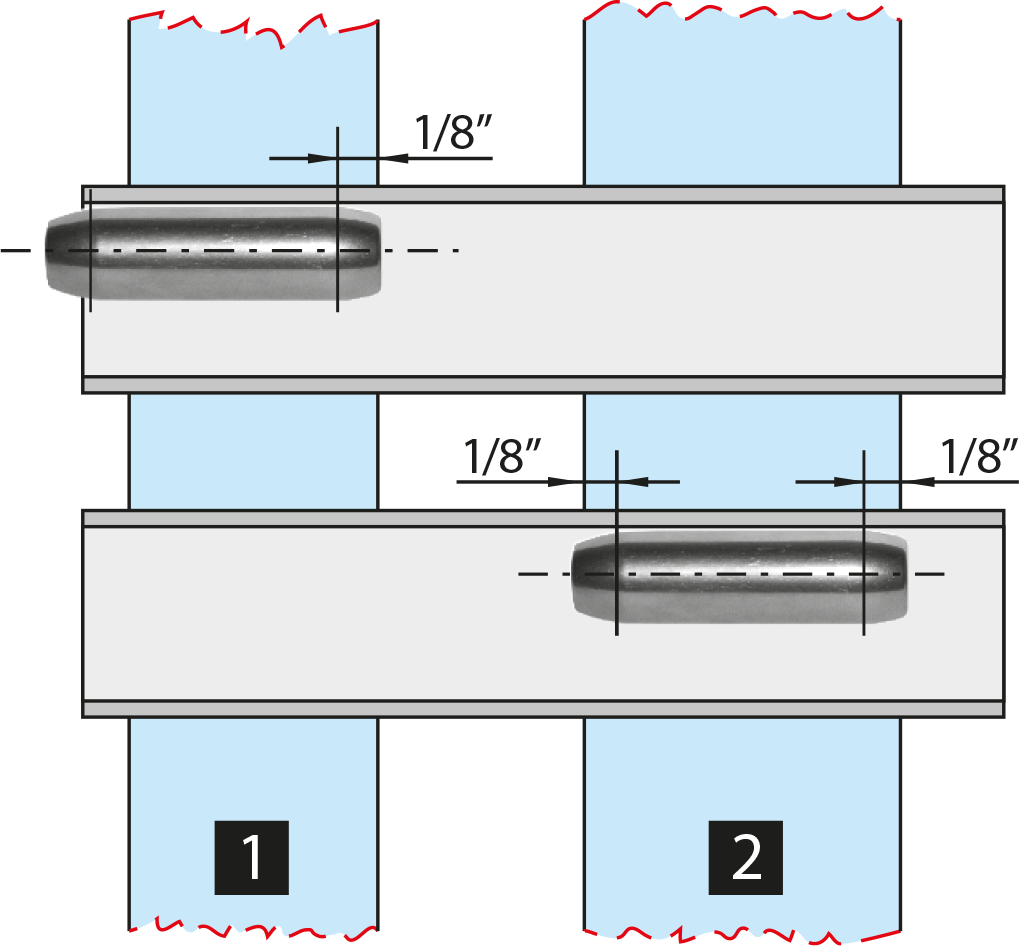

Double tube sheet application

Primary tube sheet would be rolled with a 800 type expander with roll located per example.

Effective length of roll to be specified based on secondary tube sheet thickness.

Secondary tube sheet would be rolled with a 1200 type expander with „2R” type rolls as per example.

When rolling a secondary tube sheet always use „2R” type rolls. Position expander so that the roll straddles the tube sheet with the high points approx 1/8” inside front and sack of the tube sheet.

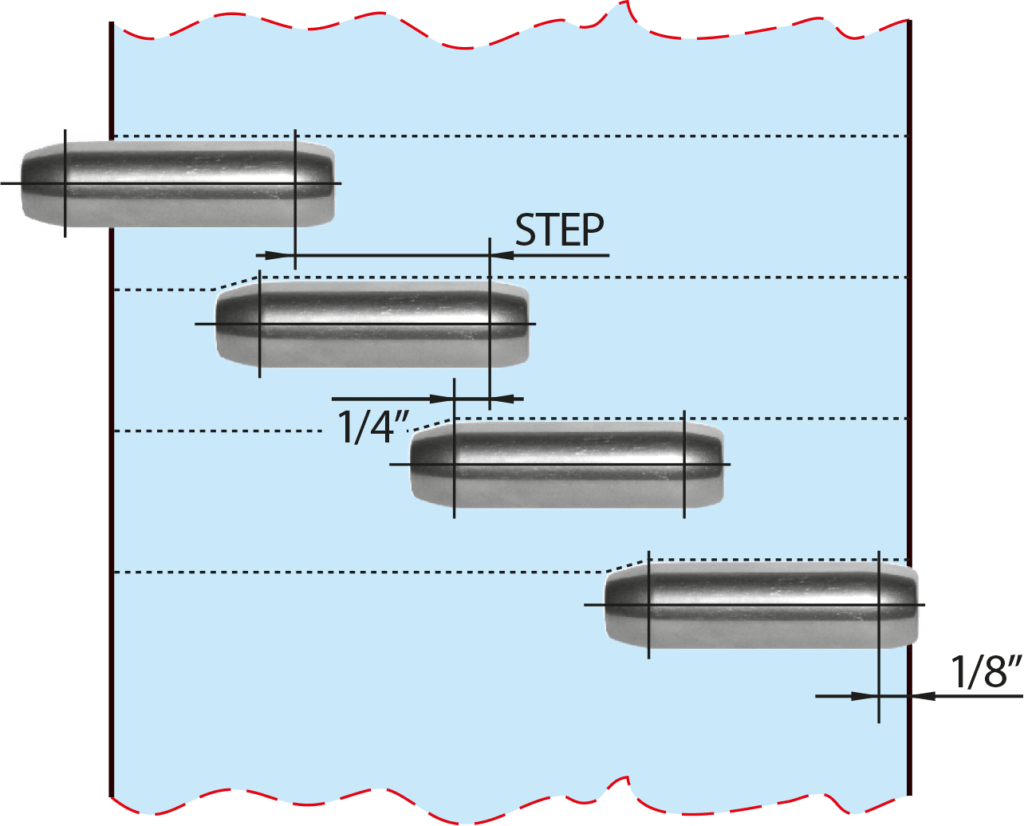

Step rolling for thick tube sheets

To determine length of steps, divide the estimated number of steps into the length of area to be rolled. This length must be at least 1/4” shorter than the effective length of the “2R” roll.

Note! 1-1/2” long rolls have maximum effective length of 1”; 2-1/4” long rolls have maximum effective length of 1-3/4”